Material Jetting Development Just Got Easier

At Added Scientific Ltd we do a lot of research with inkjet printheads. To offer our customers the best results for their investment we are constantly on the lookout for the most cost effective solutions. Entry-level systems for developments in material jetting are unfortunately rare, so, as we have a great team of engineers, we made our own!

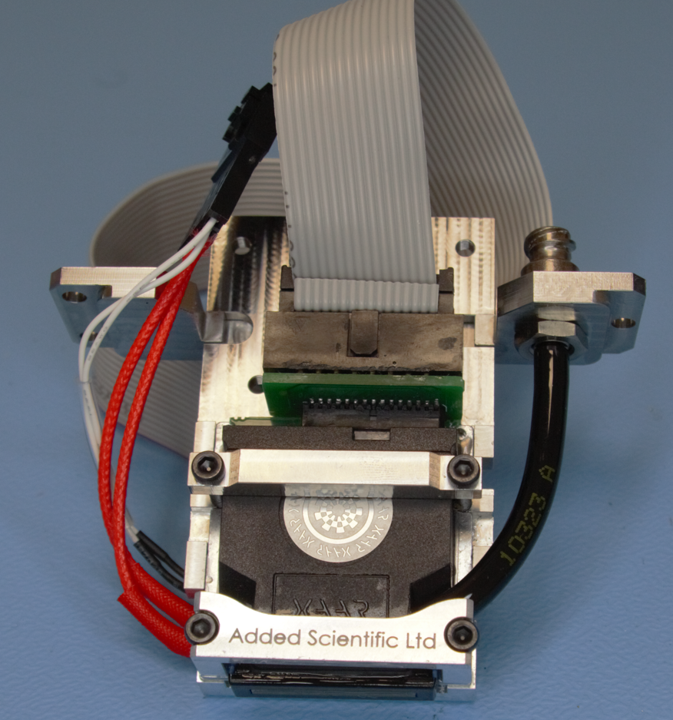

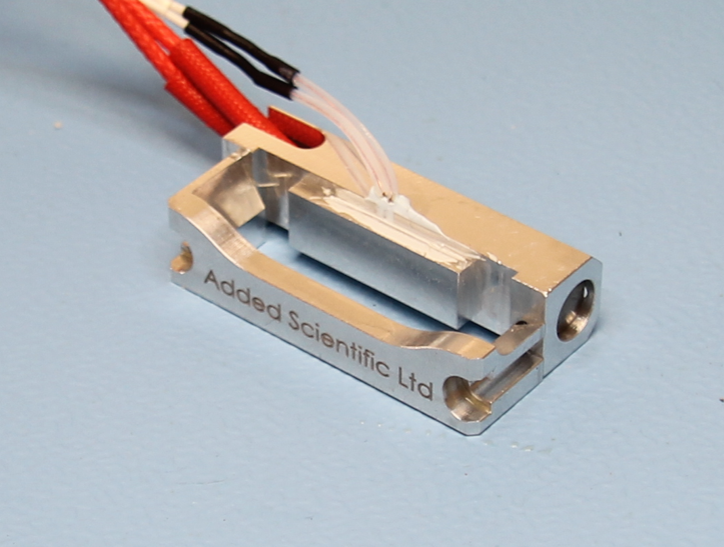

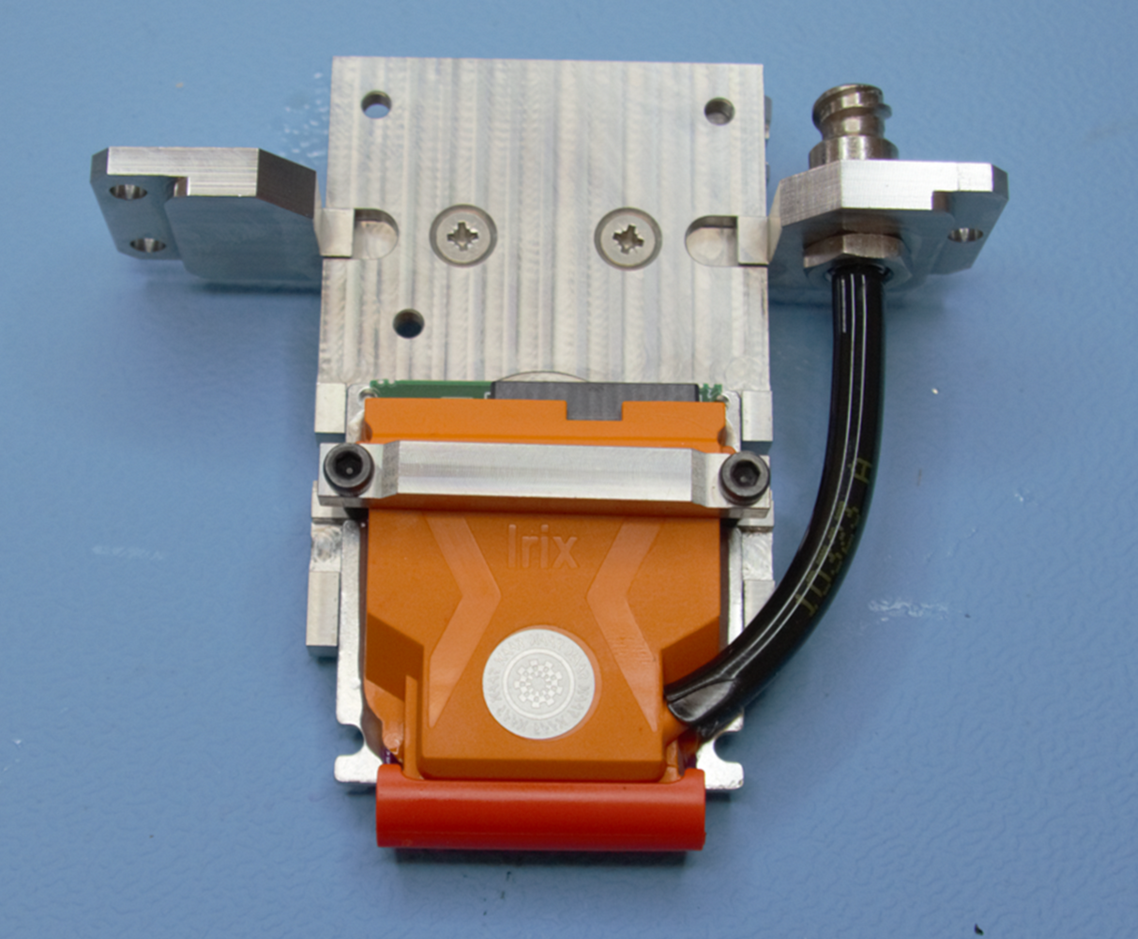

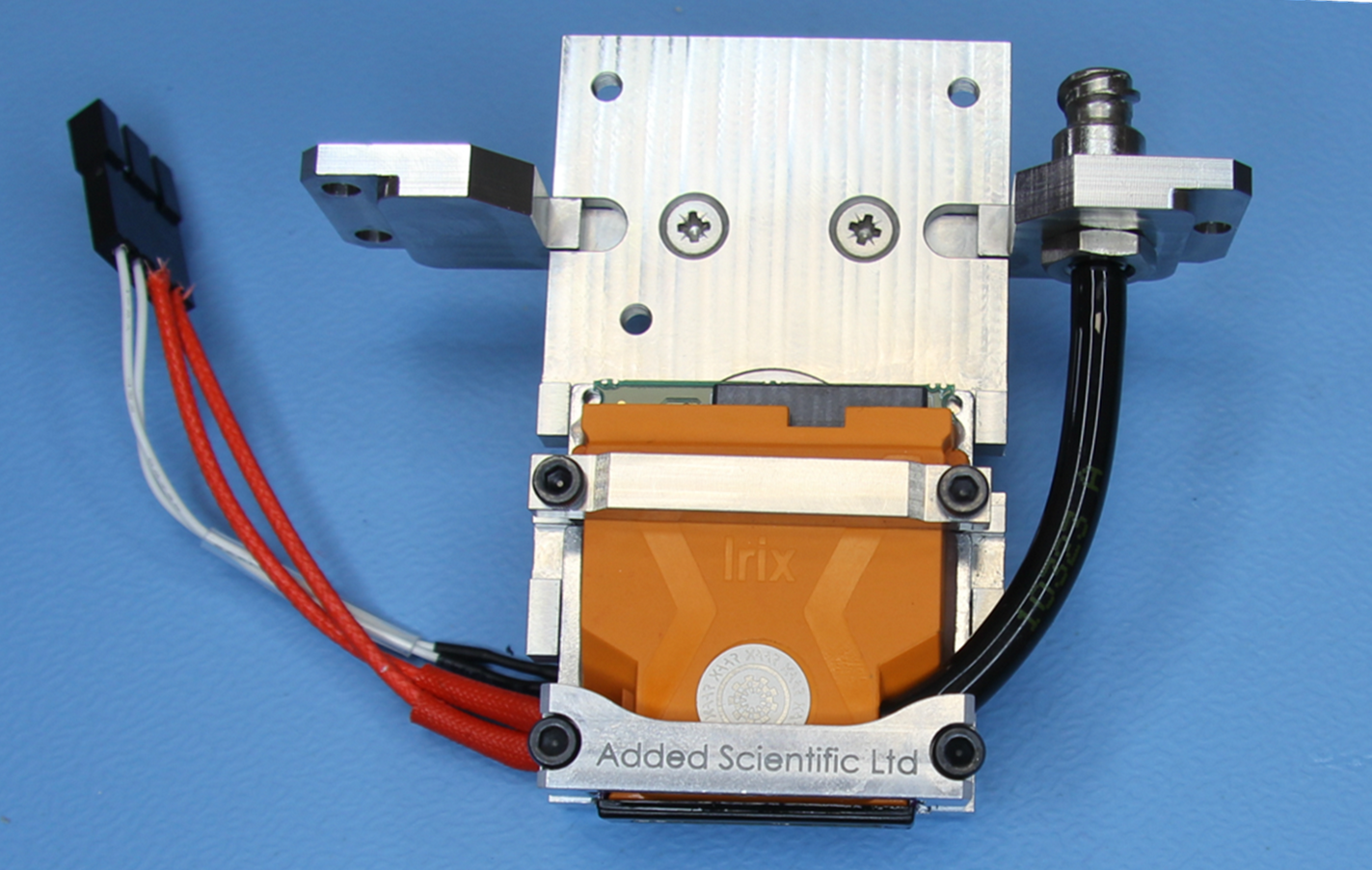

We have selected a printhead with 40 - 80 pL native drop volume, resulting in faster printing and thicker layers. The printhead comes with a small ink tank volume and our mounting equipment enables the use of a 1 mL syringe to use < 5 mL of ink during development. With the luer fitting syringes can be used as ink tanks and rapid cleaning and switch over is possible.

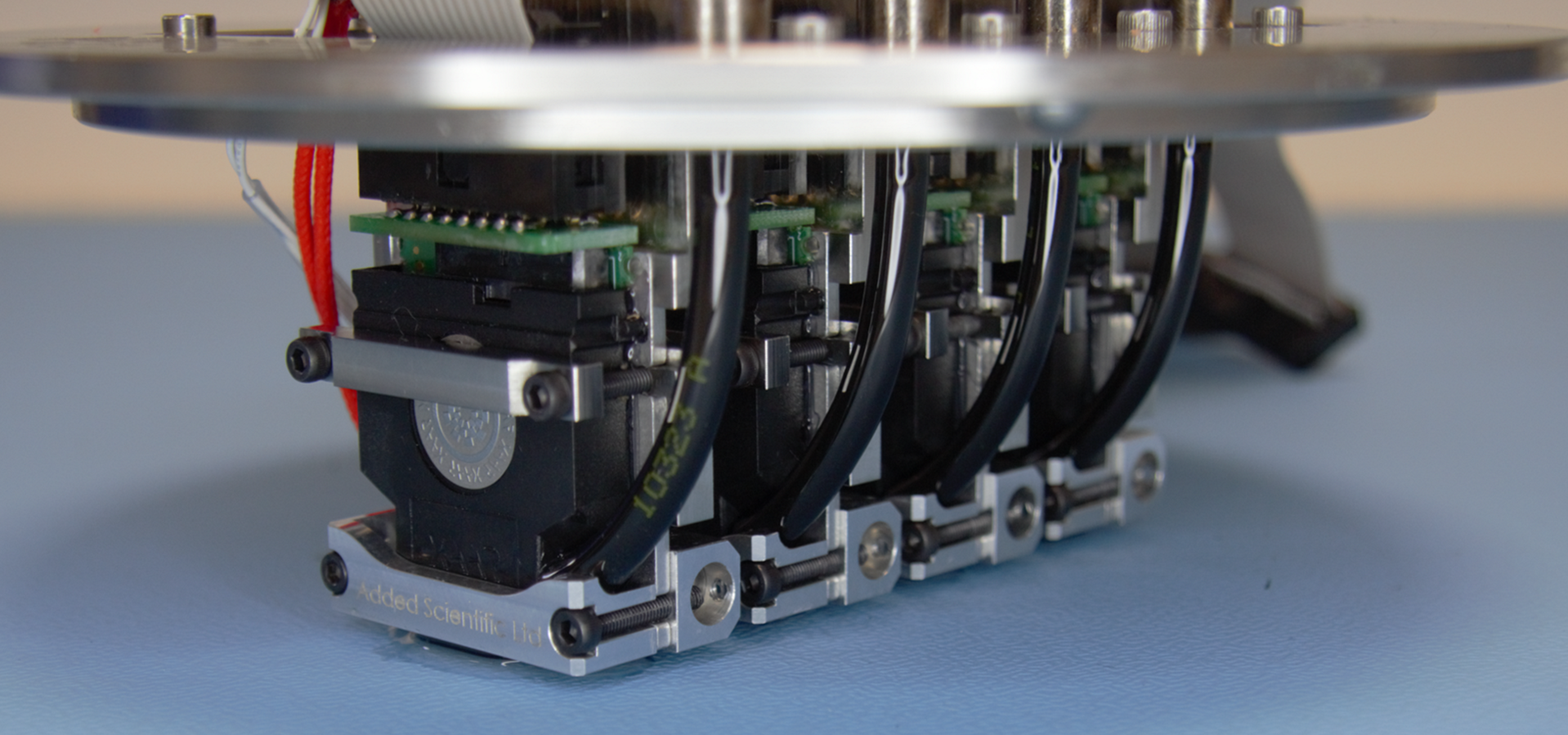

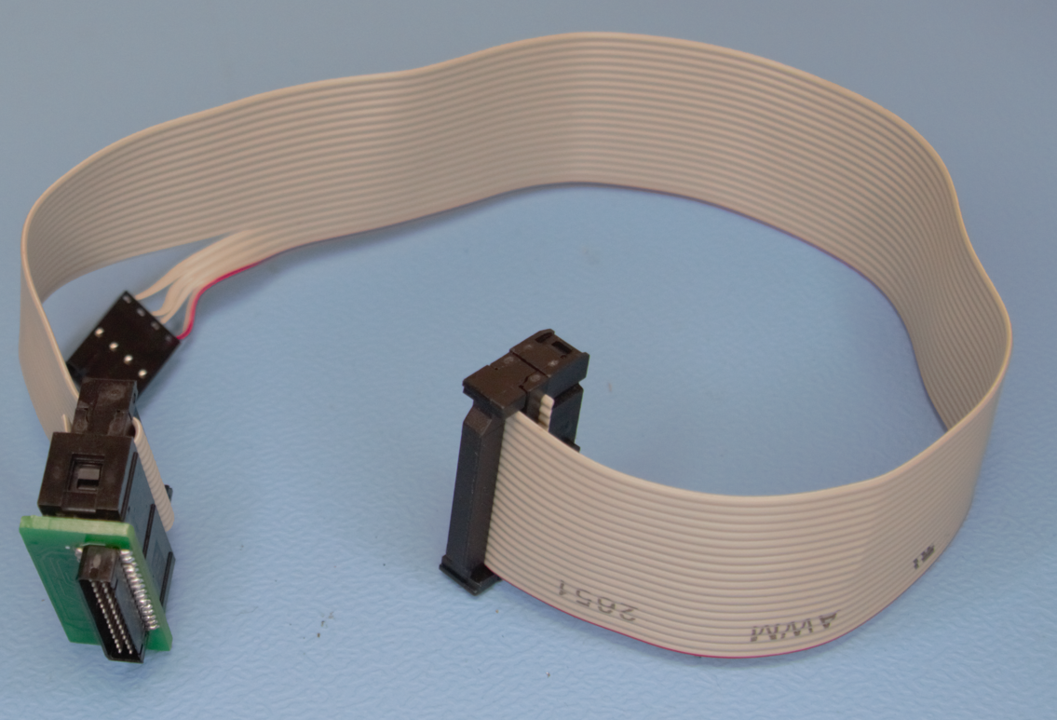

The driver board we have supports multiple interfaces and allows for the use of up to four heads on a printer. Here we show our custom LP50 mount but other printers can be accommodated.

The board can either create it’s own strobe synchronisation signal or accept one from an external source. This means it is compatible with all major drop watchers on the market.

With our drive electronics you get control over all the parameters you need for material jetting development including:

Printhead temperature

Jetting voltage

Waveform duration

Fully scriptable interface

Check out the datasheet here.